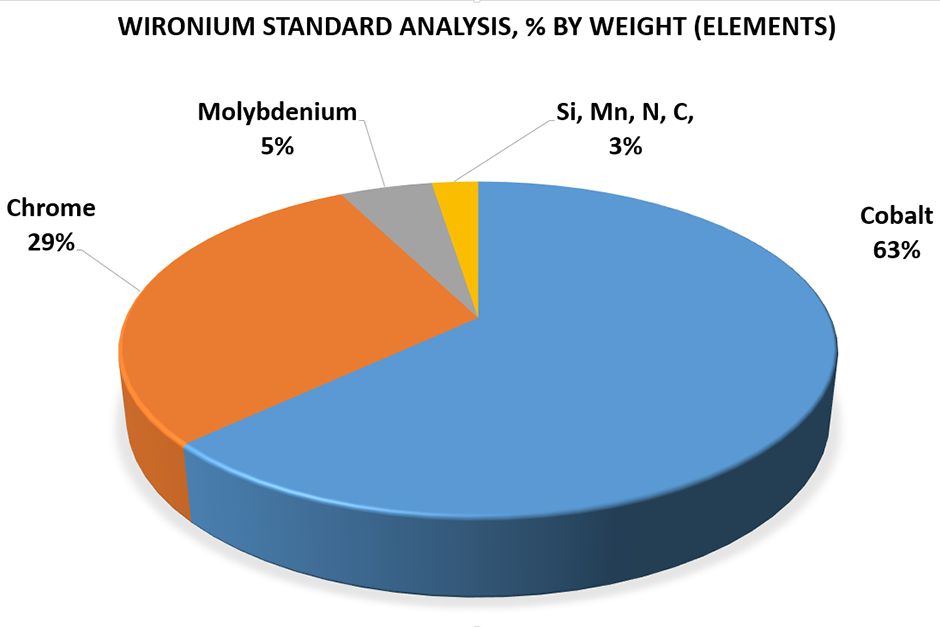

Chrome

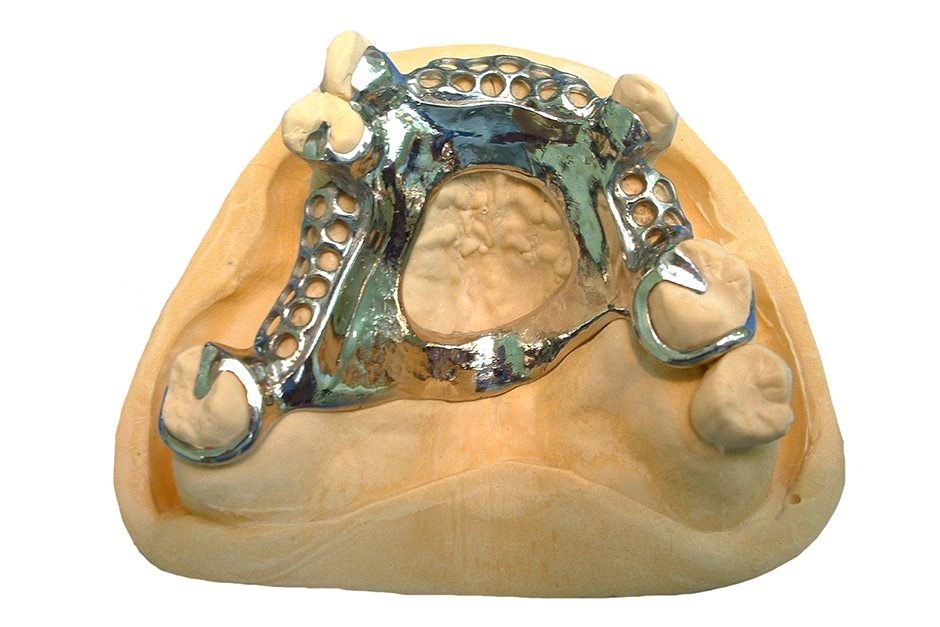

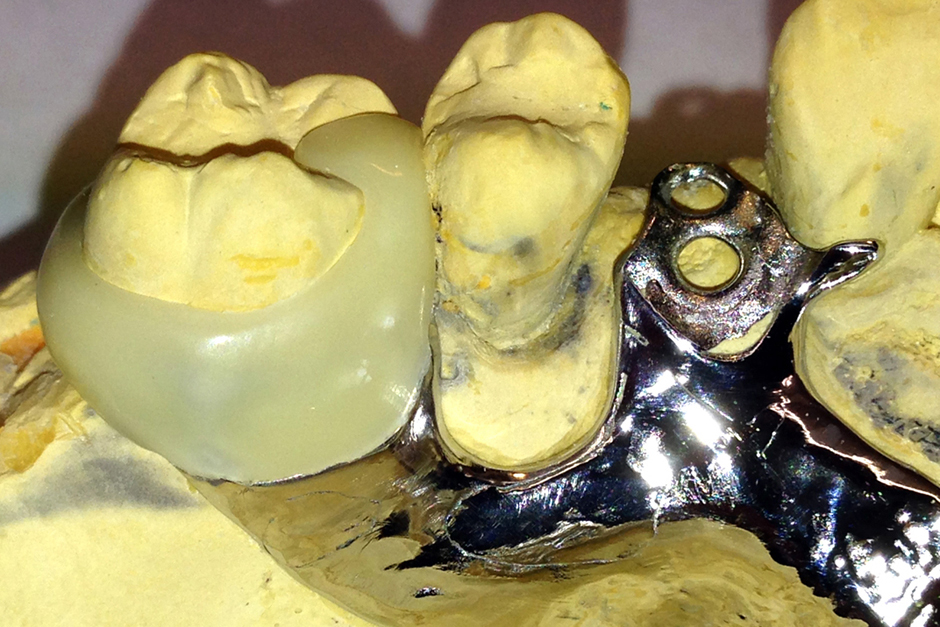

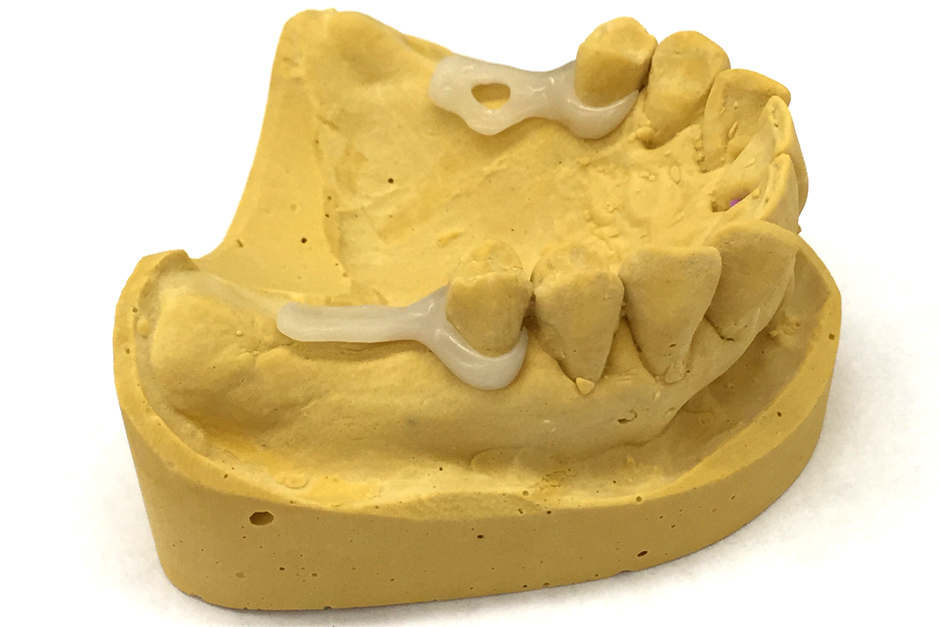

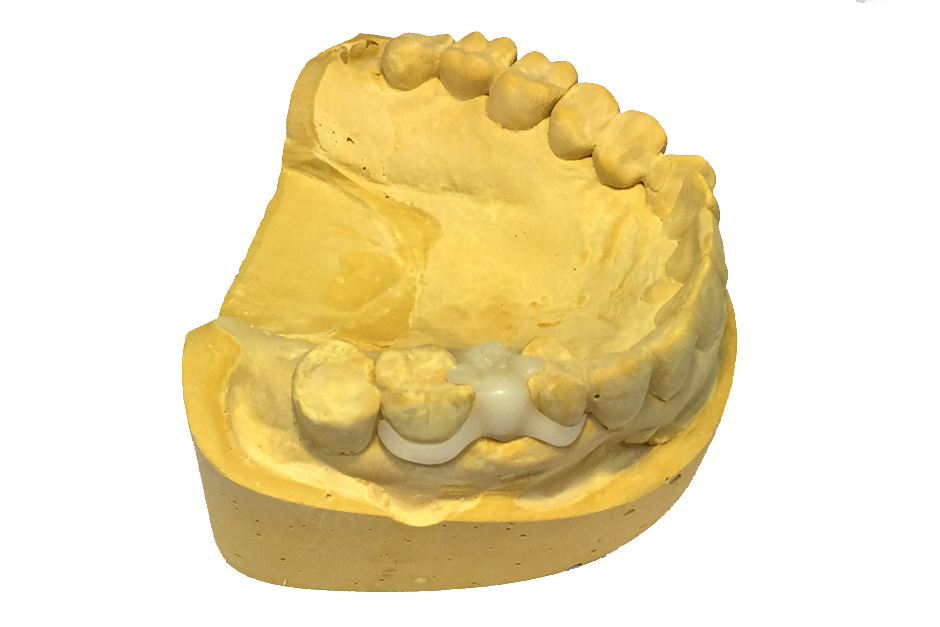

Spider Chrome Framework

Here at McDowell + Service we pride ourselves on our attention to detail and that is why we only use the best CE materials and by adopting the BEGO system we produce high quality precision frameworks.

Our chrome frameworks are cast using BEGO’s Wironium® Alloy which exceeds all International Standards and allows us to produce very fine but strong dentures which resist even the highest of masticatory forces.

For greater accuracy, we always recommend a special tray impression, taken in either rubber or alginate. Finished frameworks are returned on the master model to ensure the accuracy of our work.

We are proud to be members of the International Wironium Circle which is a worldwide association of leading dental laboratories which share a single goal to provide first-class dental work using top-quality materials.

The high standards of quality demanded from I.W.C. member labs, ensure the reliability which dentists and patients require. Regular training, conferences, and symposia keep IWC members informed and at the leading edge of their industry.

Know-How Training and collaboration keep I.W.C. laboratories ahead of the competition. Laboratories who display the I.W.C. symbol demonstrate that they use the best materials and cutting-edge knowledge and equipment. If requested, we can provide complimentary patient information and custom framework designs, for surgeon or patient approval.

The System we use is Bego’s Partial Denture Technique

Wironium alloys are processed in a special, carefully matched chain of materials using the proven BEGO cobalt-chrome system. Dentists prefer Wironium frameworks because of better fit, guaranteed reliability, comfort, and durability for the patient.

.jpg)