Titanium

Titanium

Titanium is the most bio-compatible metal known and is very high tech in the world of dentistry.

It has a variety of applications, not only used in the aerospace industry but also in many different areas of medicine. Titanium forms a passive and protective oxide coating which increases its corrosion resistance and so is a compatible alternative for patients with allergies.

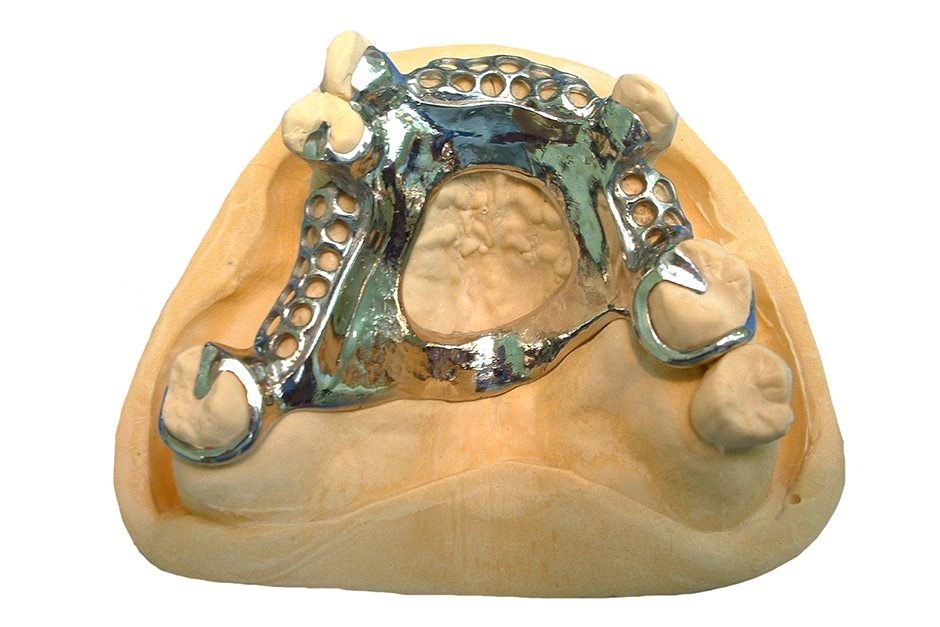

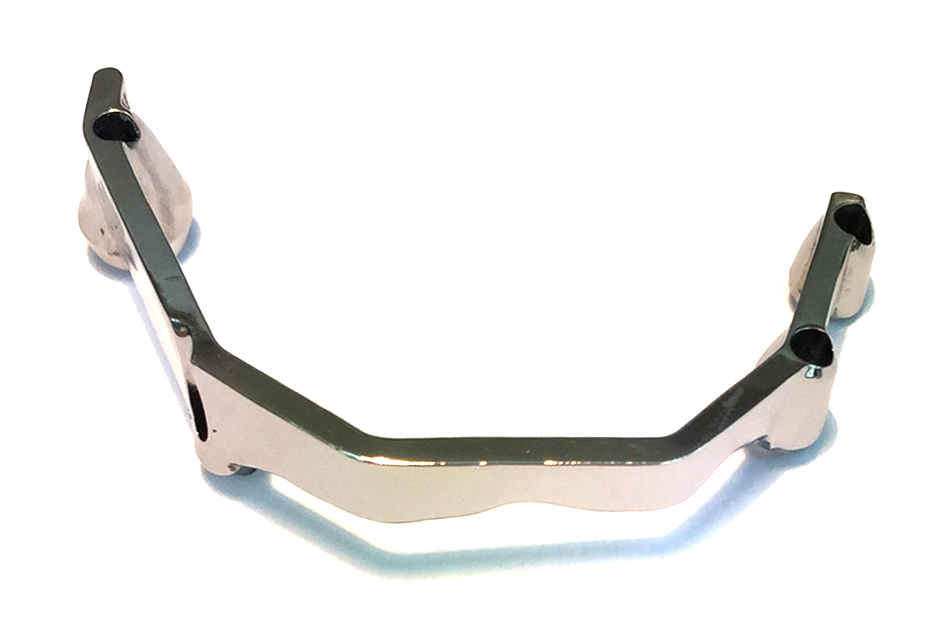

For our partial dentures, we use the Titan brand of titanium obtaining absolute bio-compatibility due to its high chemical purity which is a minimum of 99.5%.

Our dental frameworks are cast using Grade 4 titanium and have higher figures of elongation, proof stress and elasticity.